KHS line design in 3D and virtual reality: efficient conception and on-site installation

KHS GmbH is consistently further developing its virtual line design program to include 3D visualization and a virtual reality (VR) environment.

- Mobile VR systems for customer line visualization on site

- Planners and design engineers linked up for fast changes

- Training scenarios for site personnel prior to installation

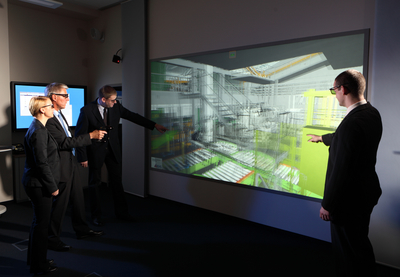

Plan and design models intelligently linked

KHS uses design engineering methods it has developed itself which ensure that the design model is semiautomatically linked up to the planning model through the PDM system. Changes to the design are made visible in the planning model and can then be updated in the 3D plan by a click of the mouse. "The system planner is thus directly linked to the designer through the PDM system – and planning errors are ruled out," says Riedel. Customers benefit from this holistic planning, as the planning phase is considerably shortened. Unanswered questions can be clarified more quickly thanks to the 3D environment and on-site installation is much more efficient. KHS is currently working on virtual training scenarios for site personnel prior to assembly. This enables them to go through the individual work processes virtually so that they are better prepared for installation on site. VR simulation helps to provide simple access to and clearly visualize complex topics.About the KHS Group

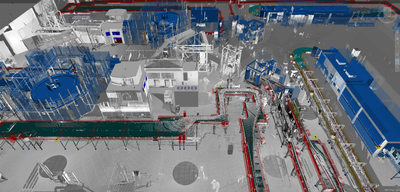

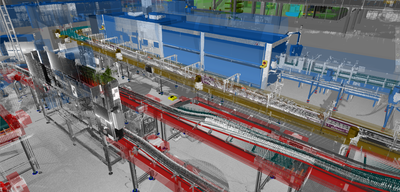

The KHS Group is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. The KHS Group includes the following companies, among others: KHS GmbH, KHS Corpoplast GmbH, KHS Plasmax GmbH and NMP Systems GmbH. KHS GmbH manufactures modern filling and packaging systems at its headquarters in Dortmund, Germany, and in Kleve, Bad Kreuznach and Worms. The KHS Group's PET expertise is pooled at KHS Corpoplast and KHS Plasmax in Hamburg, Germany, where light PET packaging and innovative coating systems are developed and produced. NMP Systems GmbH, a wholly-owned subsidiary of KHS GmbH based in Düsseldorf in Germany, designs and markets new, resource-saving packaging systems for PET bottles. The Group has an international production and service network. In 2015 KHS was awarded the Top 100 seal of approval for exceptional innovative power and outstanding innovative success among German SMEs. In 2015 the KHS Group and its 4,871 employees achieved a turnover of around €1.17 billion within the Salzgitter consolidation. The companies in the KHS Group are 100% subsidiaries of the MDAX-listed Salzgitter AG corporation.The 3D laser scan creates a seamless image of the environment from up to 200 scanned positions.

Download image (PNG, 4 MB)Following on-site installation the quality is controlled by combining the planning data with the laser scan.

Download image (PNG, 4 MB)On 3D projection screens (Powerwalls) the optimum line sequence and setup of machines are jointly planned with the customer.

Download image (JPG, 7 MB)