Packaging technology: KHS increases availability of format parts for PET lines

The KHS Group is cutting the time needed from the initial design idea to format changeovers on PET lines. This means that new formats can be realized more quickly.

- Faster processing thanks to optimized processes

- Integrated holistic packaging systems

- Changeovers focus on high line efficiency

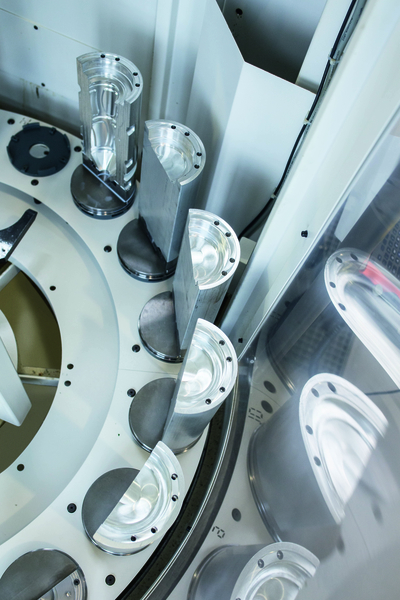

Attractive and efficient bottle design

A new bottle shape is often the reason for a format conversion. In order that the new design meets the specifications and requirements of the customer, the Bottles & Shapes™ program develops bottles which are distinguished by two main characteristics: an attractive design for consumers and a high level of efficiency on the filling line. "The earlier we start to develop projects together with our customers, the better we can influence the design of their containers," says Armin Wille, product manager of Conversions at KHS. The lightest bottle is of no use to the customer if pallets are later unstable or the output capacity drops. It is thus important to see the big picture and include all sub-functions in the project from the beginning. To ensure an optimum quality of design and engineering KHS has strengthened cooperation throughout its production sites in Design Engineering, Production, Offer and Order Processing and Logistics.About the KHS Group

The KHS Group is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. The KHS Group includes the following companies, among others: KHS GmbH, KHS Corpoplast GmbH, KHS Plasmax GmbH and NMP Systems GmbH. KHS GmbH manufactures modern filling and packaging systems at its headquarters in Dortmund, Germany, and in Kleve, Bad Kreuznach and Worms. The KHS Group's PET expertise is pooled at KHS Corpoplast and KHS Plasmax in Hamburg, Germany, where light PET packaging and innovative coating systems are developed and produced. NMP Systems GmbH, a wholly-owned subsidiary of KHS GmbH based in Düsseldorf in Germany, designs and markets new, resource-saving packaging systems for PET bottles. The Group has an international production and service network. In 2015 KHS was awarded the Top 100 seal of approval for exceptional innovative power and outstanding innovative success among German SMEs. In 2015 the KHS Group and its 4,871 employees achieved a turnover of around €1.17 billion within the Salzgitter consolidation. The companies in the KHS Group are 100% subsidiaries of the MDAX-listed Salzgitter AG corporation.The KHS Corpoplast Bottles & Shapes™ program stands for efficient and resource-saving packaging systems.

Download image (JPG, 30 KB)Conversion times for format conversions on PET lines can be reduced to eight weeks maximum.

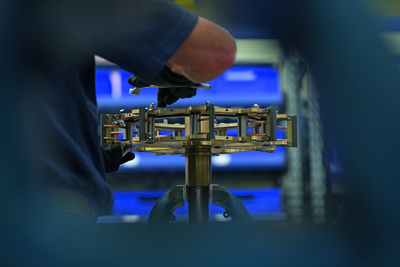

Download image (JPG, 4 MB)PET format conversions are planned in consultation with the customer.

Download image (JPG, 4 MB)KHS offers its customers attractive bottle designs and a high level of efficiency on the filling line.

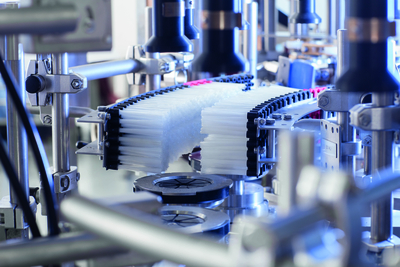

Download image (JPG, 4 MB)All line components require format adjustments - here for example a KHS labeling machine.

Download image (JPG, 7 MB)