Different from Others

The Left Hand Brewery strikes out on its own path to success – together with the innovative KHS keg technology, Innokeg Till CombiKeg

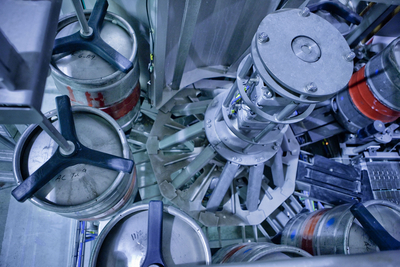

Georg Zuzok* Mike Brancato** Rainer Deutschmann*** The Left Hand Brewing Company is a "Craft Brewery" located in the US federal state of Colorado, which is striking out on its own path not only in view of the individuality of its name. This path began in the 1990's and, according to Joe Schiraldi, VP of Brewing Operations for the Left Hand Brewery, has been a lot of fun to follow for both management and employees. Schiraldi said: "This is due amongst other things to our wide assortment of beers, which includes numerous seasonal beers in addition to the classic range. Our beers are continuously being developed and, if required, newly created". Jake Kolakowski, <s>Production</s> Packaging Manager of the Left Hand Brewery, adds: "Our tradition is in fact innovation, and that makes working for the Left Hand Brewery so exciting". Innovation from tradition – this is a motto which can also be applied to the brewery's latest investment. Looking for new keg technology, the company decided on an innovation of a very special kind: the Innokeg Till CombiKeg. This is a newly-developed keg washer and racker in an extremely compact container format design which works according to the tried and tested rotary principle continuously developed by KHS over decades. This means that in this system, too, the aspects of tradition and innovation go successfully hand in hand. Convinced by the principle used on this system, the Left Hand Brewery ordered the Innokeg Till CombiKeg almost immediately after it had become ready for launch on the market, and is therefore the second brewery worldwide to profit from this new development. Kolakowski: "We were and still are excited about the many advantages of this keg line. This is a robust, reliable system which meets our high-quality standards with its particularly compact design – which is a major topic for a small brewery such as ours". * Head of Market Zone Americas, KHS GmbH, Bad Kreuznach, Phone: +49 6 71-8 52-22 02 ** Vice President of Sales & Marketing, KHS USA, Inc., Phone: +1-2 62 - 7 87-16 76 ***Global Product Account Manager Kegging, KHS GmbH, Kriftel, Phone: +49 61 92/4 91-1 30 A Christmas present with consequences The history of the Left Hand Brewery actually began with a Christmas present in 1990. Dick Doore, one of the two founders of the brewery, received a "Homebrewer's kit" in this year from his brother. Doore then brewed his own beer for three years before meeting up again with a former fellow student, Eric Wallace, Wallace had travelled the world and had always tried the very different qualities of beer with great interest – always on the look-out for something special. The two men quickly decided to brew beer together. Friends and neighbors were so impressed with their brewing results that Doore and Wallace decided to found a small brewery together. A few weeks later - November 1993, to be precise - they procured a former meat factory in Longmont, near Denver, the capital city of Colorado, and set up their business there. The two men named their brewery “Left Hand” after an Indian chief from the Arapaho tribe formerly living in the area around Longmont. The first award in the very first year In January 1994, business officially began at the brewery – with Sawtooth Ale, a brand of beer still highly successful on the market today. A major milestone at the start of the Left Hand Brewery's history was, according to Schiraldi, the company's participation in the Great American Beer Festival in October 1994. Here they were awarded their first medals, and the public's attention was drawn to the high quality of the Left Hand Brewery beer by a neutral source. Whereas Sawtooth Ale received the gold medal in the "Bitter" category, Black Jack Porter received the bronze medal in the "Porter" category. Schiraldi explained: "That was a confirmation which showed us that we were on the right track with our beer qualities, and above all gave us the courage to try out much more". 18 different beer brands Today the brewery produces 18 different beer brands, amongst these seven regular brands which are available the whole year, and eleven beer brands which change according to the season. The brand of beer which sells most at approx. 35 percent is Milk Stout, a dark beer which according to Kolakowski has a flavor reminiscent of coffee with cream. It is therefore not surprising that this beer goes down exceptionally well with the target group of women, too. In second place we have Sawtooth Ale with sales of 30 percent. In third place at 10 percent, we have 400 lb Monkey, an "English Style India Pale Ale". Polestar Pilsner lands in fourth place at 6 percent, and Black Jack Porter at 6 percent in fifth place. The remaining eleven percent are distributed across the regular beer brands Stranger Pale Ale and Wake Up Dead Stout as well as the seasonal beers such as Oktoberfest, Good Juju, Warrior IPA, Fade to Black, Twin Sisters etc. The art of brewing and a high commitment to quality The flow of awards for Left Hand beer qualities didn't stop in 1993. A large number of other medals have been added since 1994. For example, the brewery has received a total of 15 medals at the Great American Beer Festival over the years. Eight medals have been won in the World Beer Cup; amongst these the gold medal for Milk Stout in 2006 and 2008. Another three medals (two of these gold medals) were awarded at the European Beer Star and one gold medal was awarded to the Left Hand Brewery during the International Beer and Whiskey Festival in Stockholm. Schiraldi: "We are so proud of our awards above all because each one documents our brewing skills and our high commitment to quality. And because we can thereby demonstrate amongst other things that excellent quality always comes before quantity". More than 50 percent sales growth planned in 2011 Even if the Left Hand Brewery does not consider quantity as important as quality, sales increases went, and still go, hand in hand with consumer's perception of the high beer quality. The brewery began in 1994 with annual sales of 1,400 hectoliters and reached 11,000 hectoliters by 2002. From 2002 the growth curve rose even more steeply for the Left Hand Brewery, in Schiraldi's opinion amongst other things due to the decision to sell off a beer wholesaling company founded in 1998. Schiraldi: "We founded the Indian Peak Distribution Company because we were sure that we as ambitious brewers understood our beer best and therefore would be able to market it best ourselves. At the same time we integrated beer brands from numerous other small breweries into our range, thus giving these breweries additional sales opportunities. However, we began to realize that this was not allowing us to concentrate fully on our main business, the brewing of beer, and we were courageous enough to sell the Indian Peak Distribution Company in 2002. In retrospect, this was exactly the right decision". Thanks to this decision, the Left Hand Brewery was really able to grow. Sales in 2010 of 30,000 hectoliters confirm this fact as well as the planning for 2011, which, according to Schiraldi, "is not too ambitious with an estimate of around 50,000 hectoliters". Export to numerous US states and Europe The Left Hand Brewery is still extremely active in its home market of Colorado, making approximately 40 percent of its sales there. At the same time, however, Left Hand beers are also selling well in 26 other US states. And then there are exports to Europe. Whether in Great Britain, Sweden, Norway, Holland or Italy – Left Hand beer brands are everywhere. Schiraldi said: "Our future planning includes strengthening our position on the US markets and increasing our export activities". Distribution exclusively in glass bottles and kegs Left Hand beer brands are distributed both in glass bottles and in kegs. 0.35-l and 0.65-l glass bottles are used. The range of kegs used is wider. Whereas for the US market, sizes of a half-barrel, a quarter-barrel and a sixth-barrel (1 barrel = 117.347765 liters) are provided, 20- and 30-l kegs are supplied for the European market. In general, 60 percent of the beers produced in glass bottles at Left Hand go to consumers and 40 percent is filled into kegs and distributed to the hospitality sector. Optimum keg technology for excellent beer quality Kolakowski: "Keg filling is a major factor in our brewery. It is therefore <s>all the more</s> extremely important for us to apply an excellent technical solution when filling the kegs. We decided on the one hand <s>for</s> to use KHS keg technology because we had already heard good things about KHS quality. On the other hand we see in the KHS innovation Till CombiKeg numerous advantages which are of major importance to a small brewery in particular". Capacities of up to 90 kegs per hour Operating at the Left Hand Brewery: the Innokeg Till CombiKeg, Type R 5 – equipped with five washing heads and one filling head. The machine capacity, especially oriented to Left Hand requirements, totals up to 70 kegs per hour. Depending on the requirements and the keg type, the Innokeg Till CombiKeg R 5 can generally process up to 90 kegs per hour. An exterior washing station is integrated into the housing of the Innokeg Till CombiKeg R 5. This measure serves to further improve the compactness of the system. Perfectly suited to a very wide range of keg sizes and variants In general, the Innokeg Till CombiKeg processes a very wide range of keg sizes and types of disposable and reusable kegs – starting with the 10-liter right up to the 58-liter variant. This means that it is optimally equipped for all current and any future keg variants for the Left Hand Brewery. The Innokeg Till CombiKeg is also flexible as far as the product to be filled is concerned, equipped as it is for the racking of beer, soft drinks, mineral water, fruit juice, and wine. For example, should the Left Hand Brewery in future decide to also produce soft drinks, it would be possible to realize keg racking for this purpose too. Schiraldi: " It's true that we are planning to produce just beer in the future; on the other hand, we remain highly flexible in our way of thinking and never say never! It is just good to know that KHS keg technology is also as flexible". Intelligent arrangement of infeed and discharge conveyors On the new system, kegs are positioned onto the infeed conveyor by an operator and guided directly to the Innokeg Till CombiKeg. The perfect solution: The discharge conveyor is located immediately next to the infeed conveyor. In this way one operator can both load and unload the kegs. At the same time this intelligent conveyor arrangement makes for even smaller space requirements. Integrated maximum safety Within the Innokeg Till CombiKeg, every keg is initially subjected to a leakage test after being positioned and fixed by means of a pressure cylinder, before the initial interior washing process begins. This is a procedure which is repeated on all interior washing stations as well as at the filling station. If the leakage test proves negative, the keg is cycled on through the machine, but is not treated. Maximum safety is the watchword here. Interior and exterior washing designed to be very gentle on resources Once the keg has successfully run through the leakage test, beer residues are blown out using sterilized air inside the first interior washing station. Next comes a pulsating pre-spray with mixed water in order to rinse out coarse soiling. Sparing use of resources – that is the principle here. For this reason, water collected from the last hot water spraying process conducted within the machine is used for the mixed water pre-spray. This saves on wastewater and power in addition to water. Kolakowski: "We place maximum value on sustainable production and consider it extremely advantageous that the Innokeg Till CombiKeg conserves resources". The final step inside the first washing station is the partial filling of each keg with caustic. The background to this is that the exterior washing station is positioned downstream of the first interior washing station. This means that a caustic softening process can take place inside whilst the exterior washing of the keg is being carried out. A separate passive washing station is not required. During the exterior keg washing process, the keg exterior is first flushed with mixed water. Here, too, the mixed water mainly comes from the last hot water spray and so once again water, wastewater and energy are saved. The keg is then rotated whilst a fixed nozzle holder sprays down the keg exterior, also using mixed water. Another effect caused by the rotation is that the effectivity of the caustic softening process in the keg interior is improved. The exterior washing process also has the following integrated in particular for very soiled kegs: a motor-driven brush for additional mechanical keg washing. It can be adapted to changing keg variants using an electrical adjustment motor. Focus on hygienic design Maximum hygiene – this is a concept fulfilled in every way by the Innokeg Till CombiKeg. For this reason, the exterior washer is purposely separated from the interior washing processes by protective doors. In addition, the system cladding is consistently designed according to hygienic design specifications. Pulsating washing procedure achieves excellent washing results Directly after the exterior washing process comes a second interior washing step, which starts with blowing out any caustic still inside the keg. A second batch of caustic, with which the pulsating cleaning process is started, is then introduced into the keg. This procedure ensures both perfect cleaning of the keg interior wall and cleaning of the riser pipe. In the pulsating cleaning process, cleaning liquid initially exits the riser pipe and forms a film of liquid in the keg cup that flows over the inner surface of the keg bladder, then collects at the keg neck, and, due to the overpressure in the keg, flows back out through the ring channel. The volume flow through the riser pipe is decreased at regular intervals. In this case, the cleaning medium no longer floods the inner surface of the keg bladder but instead flows as a film down the riser pipe. This ensures that all surfaces inside the keg coming into contact with the product have been coated with the fluid process medium. Targeted process monitoring This process is monitored in the same way as all other interior washing processes using two components, a pressure probe and a wet/dry detector probe. The task of the third interior washing station is a repeated pulsating cleaning process with the second batch of caustic. The fourth interior washing station is used for acid cleaning - also using the principle of pulsating cleaning and the subsequent pulsating cleaning using hot water. Finally, washing station five is used for hot water discharge and final blow-out of the kegs with steam, and then realizes the pressurization of the kegs with CO2 in preparation for the filling process. DFC filling technology for minimum oxygen pickup in the product, minimized carbon dioxide consumption and a gentle filling process. The Left Hand Brewery made a conscious decision to use the most up to date DFC filling technology, which is based on volume flow control. In general, it is sufficient to pressurize the kegs in the DFC filling process to a pressure that is slightly above the degree of CO2 saturation. This means that carbon dioxide consumption is reduced by up to 40% versus conventional racking systems. The direct control of the racking process by means of a control valve in the product infeed makes the DFC filling process extremely accurate. There is no product loss due to keg overfill, and underfilling is not an issue either. At the same time the quality of the product is maintained thanks to minimum oxygen pickup. The product is introduced into the keg starting with a slow filling phase. Once the fitting has been covered by the product, the fast filling phase begins. The filling speed is always controlled, allowing gentle treatment of the beer products. Kolakowski: "Minimum pickup of oxygen during the filling process is a major factor as it permits optimum filling quality and a maximum product shelf life". After the filling process, the kegs move to the discharge conveyor and are palletized by an operator. Should a keg not have passed a leakage test, the operator is informed via a signal. The bad keg can be reliably removed from the process. "A real gem" Schiraldi: "I can only emphasize once again how pleased we are that our new Innokeg Till CombiKeg supports us in precisely all those aspects which are of importance to us. The system provides excellent filling quality, runs sustainably and is also designed to save a maximum of space. It offers far more than most keg lines". And Kolakowski adds: "Apart from that it is easy to operate – and is also a small but sophisticated visual gem in our production area". Schiraldi: "That increases our employees' enjoyment of their work, which is of great importance to us". Further successes are planned – using KHS keg technology Those at Left Hand are of the opinion that motivated employees play a major role in determining the success of the brewery. They represent external ambassadors for the company and ensure positive word of mouth advertising which - Schiraldi is certain - in turn has a positive effect on sales. The Left Hand Brewery is able to prove the positive effects of motivation already in a small setting. For example in the pub integrated into the brewery. Here visitors can taste all Left Hand brands of beer and can sense the motivation of Left Hand employees. This is certainly one reason why the pub is so popular with the general public. Another reason for the positive feedback from people is, according to Schiraldi, the fact that numerous events such as concerts, beer tasting, art exhibitions etc. take place here. An interesting fact: The "Tasting Room" has in the meantime developed into a ‘hot spot’ for women. For example, one of the first US beer clubs for women called Ales4Females holds regular meetings here. Schiraldi: "In the future we are planning to set innovative examples in the "Craft Brewer" market with new ideas and new developments. This makes working at the Left Hand Brewery fun for all employees and allows the company to strike a path in the direction of further successes". And as Schiraldi and Kolakowski explicitly emphasize, these successes will in part be supported by highly flexible KHS keg technology.