KHS stretch blow molder pays off after two years

An investment well made: Herzog Mineralbrunnen Schäfer Betriebsgesellschaft mbH from Bochum, Germany, now makes its own PET bottles. The mineral water bottling plant made the decision to procure its own stretch blow molder together with KHS GmbH from Dortmund, also in Germany.

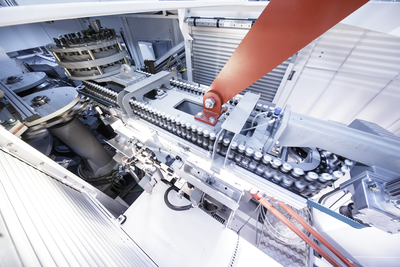

Dortmund, October 13, 2015 – An investment well made: Herzog Mineralbrunnen Schäfer Betriebsgesellschaft mbH from Bochum, Germany, now makes its own PET bottles. The mineral water bottling plant made the decision to procure its own stretch blow molder together with KHS GmbH from Dortmund, also in Germany. Their acquisition will pay off in just two years – and Herzog Mineralbrunnen is already profiting from new capacities and a new liquidity. At the end of 2014 plant manager Gerd Stork had long been toying with the idea of no longer buying in ready-made PET bottles but producing them himself at the site in Bochum. There were several reasons for not doing so, however: there was not enough room for the new system, the effort involved in converting the engineering seemed too great and the existing production setup was established and running well. Stork needed a partner who was able to offer him advice and active support. He came across the right people quite by chance at BrauBeviale 2014 in Nuremberg. The man he found himself sitting next to at an evening event was Frank Fretwurst, head of Area Product Management for KHS Corpoplast GmbH. The two got talking and at the end of their conversation Fretwurst was also convinced that the Herzog bottling plant held certain potential for making savings. Stork and Fretwurst stayed in contact and KHS drew up a sample calculation for the plant manager. If he continued buying in his bottles as he had done for the past ten years, nothing would change. In the best case the price for the bottles would not increase. Fretwurst's alternative suggestion, however, was to purchase a KHS InnoPET Blomax Series IV stretch blow molder with extremely low operating costs. All Herzog Mineralbrunnen would have to do was buy in PET preforms which are much cheaper than finished bottles. These would then be manufactured on site. Stork was quickly convinced by the calculation. "The figures speak for themselves. In two years we'll have recovered the cost for the system," says the expert beverage industry process manager. The infrastructure also had to be right, however. He thus approached the company's in-house master electrician, Stefan Czerwinski. The following challenge presented itself: a new system would need an extension connected to the existing filling section by conveying segments. The KHS InnoPET Blomax Series IV may be extremely energy efficient but the site in Bochum did not have the necessary electrical power, meaning that new cables had to be laid and the transformer house expanded. As the two men planned and played through the new scenario, they continued to be convinced by the investment. The same went for managing directors Thomas and Ralf Schäfer after they had been presented with the idea. The savings made were worth the effort. A company with tradition The two managing directors are not the first Schäfers to head the company; Herzog Mineralbrunnen evolved from a beverage wholesalers founded in 1927 by Willi Schäfer. Stork has been with Herzog for 43 years now and has thus worked for several generations of the family. In 1978 the two sons Fritz and Willi Schäfer took over the management of what had become two company units, namely production and wholesale. The family business has now been chaired by Thomas and Ralf Schäfer since 1999. Today, 17 springs within a radius of one kilometer are in operation. In addition to the Lohberg brand Herzog Mineralbrunnen also markets Engelbert and Coronet mineral water and Herzog Life, the latter specially filled into elegant, blue glass bottles for the hospitality trade. Own brands commissioned by well-known commercial enterprises are also produced. Herzog is thus a traditional Bochum company which has grown over many years in the heart of the Ruhr region and is now a fixed feature on the local business landscape. Moving towards greater efficiency Stork again contacted KHS. The figures were right; he now wanted to see the machinery for himself. He first visited the KHS production shop in Hamburg and toured the factory and then went to Stuttgart. "We had a look at a stretch blow molder already in operation together with KHS," explains Stork. He stood in front of it for a long time, he remembers. "The Blomax just kept on running. Our decision was thus made." The order was placed with the filling and packaging specialist in March 2015, a few months after first meeting up at BrauBeviale. The first self-produced PET bottles were scheduled to be filled in Bochum in August. An extension covering an area of 128 m2 was erected with plenty of room for the compact KHS line. At the same time Czerwinski took care of the infrastructure. In total Herzog Mineralbrunnen invested around €1.6 million in their new engineering setup. To cover the time needed for conversion Stork had the plant produce in advance for a week to ensure a ready supply to customers. Things went as planned; on August 14, 2015, Herzog put the system into operation. Since then everything has been running round the clock without any problems. Energy efficiency and high performance The KHS InnoPET Blomax Series IV stretch blow molder turns PET preforms into bottles. The model in Bochum has a capacity of up to 13,500 bottles per hour which gives the medium-sized family business a capacity utilization of around 80%. The high-performance versions in the KHS InnoPET Blomax Series IV achieve outputs of up to 81,000 bottles an hour. The energy efficiency and compact design of the machine were major criteria in Herzog Mineralbrunnen's decision to invest. The quality of the bottles was also not allowed to suffer, of course, and these continue to have both optimum stability and be low in weight. "It's important that production doesn't stop. All of our lines run continuously," states Stork. Approximately 35% of all products leave the production line in PET, with the rest in glass. "The percentage of PET is growing, however," he says. The plant in Bochum fills about 29 to 30 million PET bottles a year. To meet the varying demands of their production operations, the heater on the KHS InnoPET Blomax Series IV can be used in combination with any type of transfer and blow molding equipment. Because the heater is modular, upgrades such as additional heating chambers can easily be installed at a later date. The stretch blow molder can also be adapted to cater for any extensions to the product portfolio whenever needed. The sustainability of his company's investment, coupled with the close cooperative partnership with KHS, prompts Stork to proclaim, "I'm so pleased!" The high degree of process stability and machine availability of the low-maintenance system allow him to look back on the past few weeks after commissioning with satisfaction. "In two years the system will have paid off. We have more line availability and are more flexible," he smiles. For family-run SME Herzog Mineralbrunnen, a chance meeting and a decisive management have resulted in an investment which has proved successful on all counts. About KHS GmbH KHS GmbH is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. Headquartered in Dortmund, Germany, the company has an international production network with over 4,600 employees worldwide. In 2015 KHS was awarded the Top 100 seal of approval for exceptional innovative power and outstanding innovative success among German SMEs. KHS GmbH is a wholly owned subsidiary of Salzgitter AG. With around 25,000 employees throughout the globe the German steel and technology group achieved a turnover of over €9 billion in the 2014 business year. Within the Salzgitter Group the KHS Group and two other special machine manufacturers make up the Technology Division and are part of the core business of the MDAX-listed corporation.