New sustainability report: KHS focuses on its responsibility to the climate

In its new sustainability report for 2017/2018 KHS documents its various sustainability measures, successes and targets.

- Long-term goal: to cut carbon emissions

- Customers benefit from resource-saving machines

- Employee expertise drives sustainability

Dortmund, October 10, 2019 – In its new sustainability report for 2017/2018 KHS documents its various sustainability measures, successes and targets. The latest publication focuses on saving resources within the company and as regards product and service concepts.

“KHS has always attached immense importance to protecting people, the climate and the environment. In our sustainability report we show which measures we’ve already taken and which we are yet to implement in this respect,” says Kai Acker, CEO of the KHS Group. The Dortmund systems supplier’s third voluntary report is again based on the globally recognized sustainability reporting standard developed by the Global Reporting Initiative and on the sustainable development goals set by the United Nations.

Concepts for the future

“We aim to continue producing holistic systems and solutions for our customers and at the same time protect the environment,” states Acker. To this end KHS intends to lower its carbon emissions in the long term by making considerable savings in energy, materials and resources – and not just within its own company but also regarding its product and service concepts. In this way the Dortmund engineering company is helping its clients to reach their own sustainability targets.

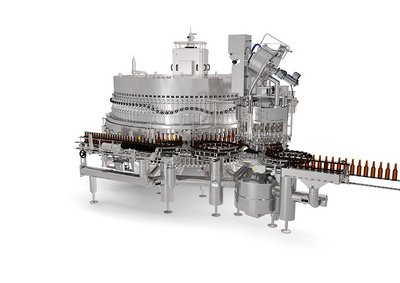

The most recent example of this is the next generation of the KHS Innofill Glass DRS ECO glass filler, distinguished by its lower energy consumption which is reduced by up to 20%. The machine also cuts carbon emissions by as much as 50%. Thanks to digital networking and monitoring the glass bottle filler also provides optimum product quality and higher line availability. “By increasingly applying intelligent products and solutions we can also boost the efficiency of our plant engineering,” Acker explains.

Employees a source of innovation

One core component of the KHS sustainability report is the company’s personnel. Besides providing a number of facts and figures the machine manufacturer gives readers an insight into the diverse fields of work covered by its many employees and their specific commitment to sustainability over the past two years. “Our employees are of central importance to KHS. It’s they who are behind every single idea and development and who are largely instrumental in promoting our economic and sustainable actions,” emphasizes Acker. In the future KHS will continue to intensify its development in the context of climate and environmental protection and check into which process steps further measures can be integrated.

The KHS sustainability report has been published every two years since 2015. The full report can be viewed online.

About KHS GmbH

KHS GmbH is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. The KHS Group includes the following companies: KHS GmbH, KHS Corpoplast GmbH and numerous subsidiaries outside Germany, located in Ahmedabad (India), Sarasota and Waukesha (USA), Zinacantepec (Mexico), São Paulo (Brazil) and Suzhou (China).

KHS GmbH manufactures modern filling and packaging systems for the high-capacity range at its headquarters in Dortmund, Germany, and at its factories in Bad Kreuznach, Kleve and Worms. The group's PET expertise is pooled at KHS Corpoplast GmbH in Hamburg, Germany, where innovative PET packaging and coating systems are developed and produced. KHS is a wholly owned subsidiary of the SDAX-listed Salzgitter AG corporation.

In 2018 the KHS Group and its 5,081 employees achieved a turnover of around €1.161 billion.

Innofill Glass DRS ECO

The next generation of the KHS glass filler is just one example of how beer, mixed beer beverages and soft drinks can be processed gently and efficiently while protecting the environment.

Download image (JPG, 91 KB)