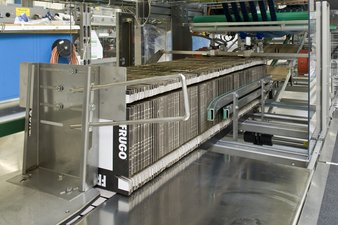

Innopack Kisters TSP Basic tray shrink packer

Efficient packaging technology for flexible production

Good to know

Increasing demands for a compact and economic packaging machine call for an optimized system – demands our Innopack Kisters TSP Basic meets exactly. This fully automatic packing machine enables flexible production of trays, film-wrapped trays, film-wrapped pads, and film-wrapped packs. With its extremely varied number of pack and loose product packaging formats for PET, glass, and cans, our Innopack Kisters TSP-B has a very broad product spectrum. The economical tray shrink packer is ideal for use in the low to medium capacity range of up to 3,600 packs per hour for the production of trays, film-wrapped trays, and film-wrapped pads, and can manufacture film-wrapped packs alone at a rate of up to 7,200 packs an hour. Using printed film also allows you to present your products successfully and thus increase your sales. Our range of services provides a reliable supply of spare parts and offers a number of conversion options to keep your line powerful, sustainable and future proof.

Well thought out

By using control technology implemented worldwide we offer you optimum availability of spare parts and service in addition to easy integration of the packing machine into your existing systems. With the integrated high-tech film cutting and feeding system you can process very thin shrink film. The Innopack Kisters TSP-B gluing system also works with the utmost precision, so that your glue consumption is kept to a minimum. The provision of a shrink tunnel heated by either gas or electricity also gives you the option of implementing the most cost-effective form of energy. Using film made of 100% recycled material also reduces the packaging’s carbon footprint without any detriment to the pack stability or flawless appearance at the point of sale. Our product-optimized shrink technology gives you excellent packaging quality – at all times.

Convincing

- Fast and easy format changeovers for optimum flexibility

- Top quality standards ensure a machine availability of up to 98%

- High-precision folding of the cardboard blanks and perfect film positioning ensure a minimum use of materials

Sustainable

- Reduce your spare part costs thanks to a low number of wear parts

- The optional gas-heated Eco shrink tunnel cuts your energy costs by up to 50% and CO2 emissions by up to 60%

- Cut your carbon emissions by up to 65%* by using film made of fully recycled material.

* According to market information from various film manufacturers

Options

-

Film made of 100% recycled material

Brief description: All KHS shrink packers can also be converted to this type of film. This upgrade can usually be easily retrofitted during ongoing production.

Benefits: By switching over to film made entirely of recycled material, you can significantly cut your carbon emissions in the packaging process in the long term without having to do without safe, high-quality secondary packaging.

Convincing: Should you have any questions about possible film thicknesses, shrink results or appearance, please feel free to contact us. On request we can test the film provided by your supplier at our special film laboratory for these parameters and give you the go-ahead for conversion quickly and reliably.

Consumables

KHS MULTI GREASE 01

KHS MULTI GREASE 01 is an high performance extreme pressure lubricant. It is suitable for centralised lubrication systems.

Material numbers: 301142150102, 301142150106, 301142150108

KHS HIGH PRESSURE GREASE 02

KHS High Pressure Grease 02 is a water resistant extreme pressure lubricant.

Material numbers: 301142150204, 301142150210, 301142150202

KHS BEARING GREASE 06

KHS Bearing Grease 06 is specially developed for the grease lubrication of machinery in the food and beverage processing and packaging industry.

Material numbers: 301142150606

KHS GEAR FLUID 220

KHS Gear Fluid 220 is a fully synthetic high performance gear oil with EP properties.

Material numbers: 301142110507

KHS GEAR FLUID 460

KHS Gear Fluid 460 is a fully synthetic high performance gear oil with EP properties which have been specially developed for use in machinery used in the food and beverage processing and packaging industry.

Material numbers: 301142110207, 301142110209

Innocoll HMP 3081

The product is used for carton and card board boxes sealing and making, tray making in very fast machines. The adhesive has a good "hot tack", very low odour and a good thermal stability.

Material numbers: 301244605220

KHS CHAIN FLUID 150

KHS Chain Fluid 150 is a fully synthetic high performance, anti-wear chain oil which have been specially developed for use in machinery used in the food and beverage processing and packaging industry.

Material numbers: 301142110105, 301142110107