Flexible and future-proof

In the search for environmentally-friendly secondary packaging, wrapping containers in paper is a further useful alternative in your packaging portfolio. With the Innopack Kisters paper system recently developed by KHS, beverage and food cans and cylindrical containers can be wrapped as packs of 12 or 24, for example, at a rate of up to 6,000 units per hour on all Advanced machines. As the machine concept is modular, existing systems can also be converted by making just a few adjustments. This allows you to react quickly and flexibly to changing requirements. Position yourself as a sustainable stakeholder in the industry now; we’d be pleased to help!

Wrapping cans in paper has many advantages over other materials. It completely replaces shrink film or the wrap-around carton, for example. The use of paper is also more ecofriendly than film – especially if we look at the pollution of our oceans – as paper biodegrades in the environment after just a few weeks. As there is no longer any need for a shrink tunnel, you also use less energy and thus cut your production costs.

Good to know

The Innopack Kisters paper system processes beverage and food cans and cylindrical containers as packs of 12 or 24, for example, at a rate of up to 6,000 units per hour.

>> Innopack Kisters TPP Advanced

Wrapping cans in paper has many advantages over other materials. It completely replaces shrink film or the wrap-around carton, for example. The use of paper is also more ecofriendly than film – especially if we look at the pollution of our oceans – as paper biodegrades in the environment after just a few weeks. As there is no longer any need for a shrink tunnel, you also use less energy and thus cut your production costs.

Improved ecobalance

Not only is your energy consumption lower; compared to the wrap-around carton, wrapping cans in paper is up to 15% less expensive. This is because there is considerably less weight involved: cardboard weighs about 400 g/m2 and packaging paper approximately 80 or 100 g/m2, for instance. Another plus is the material thickness. While single-layer corrugated cardboard is 1 to 3 mm thick, packaging paper has a thickness of around 0.1 mm. This combination of lower surface weight plus reduced material consumption results in an overall improvement in the ecobalance.

Good to know

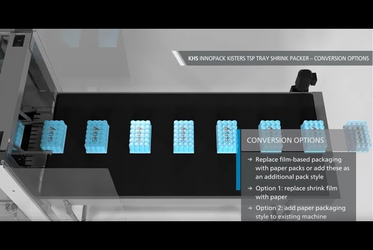

When upgrading your machinery to include paper wrapping, you can still process film. The paper folding module can be retrofitted on all Advanced shrink packers.

Sustainable on-the-shelf presentation

On the shelf, this alternative packaging variant clearly stands out from the usual types of pack. You can use this to strengthen your image as a responsible stakeholder and address an environmentally-aware clientele who will then be attracted to your product. You have a number of options when it comes to the paper quality; printed or unprinted, thicker or thinner, recycled or new, together with you we’ll find the right material for your individual requirements.

We’d be happy to advise you on the options surrounding the procurement of a new machine or a retrofit.

„Paper packaging for beverage cans is still new, but is definitely attracting a lot of interest from bottlers.“