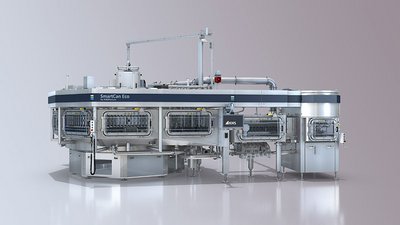

SmartCan Eco by KHS/Ferrum

The new benchmark in hygienic and efficient can filling

- Smaller hygiene area simplifies cleaning and saves space

- Modular design enables outputs of up to 135,000 cans per hour

- Use of fewer resources boosts efficiency and improves sustainability

Dortmund, September 17, 2025 – More compact, more hygienic, more efficient: the KHS Group and Ferrum Packaging AG are setting new standards in can filling with the new SmartCan Eco. With a smaller hygiene area, simplified cleaning and various other optimizations, the filler/seamer block stands for maximum quality and economy.

To underline its claim as one of the market leaders in can filling, KHS GmbH has achieved a further important milestone in its striving to make this operation more hygienic. Together with its technology partner of many years, Swiss engineering company Ferrum Packaging AG, the Dortmund systems supplier has now further developed its filler/seamer block first introduced in 2022: the SmartCan Eco by KHS/Ferrum. It scores on further improved hygiene, even higher performance and quality and numerous new features that benefit the efficiency and sustainability of this system.

Higher performance

While the filler itself is designed to process up to 135,000 cans per hour, the FS14 seamer with a current maximum performance of 108,000 cans per hour is still a limiting factor here. Ferrum’s next-largest seamer, the FS18, has the same capacity as the KHS filler and will in the future also be available for use on the SmartCan Eco. This can be integrated into the block as an option. “Depending on the seamer, our filler/seamer block can then be used for outputs of between 60,000 and 135,000 cans per hour,” explains Manfred Härtel, filling product manager for KHS in Bad Kreuznach, Germany.

High quality

Compared to its market competitors, the SmartCan Eco is primarily noted for the high quality of its proven reliable and durable filling technology. “Our filling valves are particularly appreciated by our customers for their hygienic properties, compact design and simple handling and maintenance,” states Härtel. “The valves on our computer-controlled filling system are equipped with electromagnetic induction flow meters. This ensures uniform filling volumes and that headspaces of exactly the same size are created in the cans.”

Gentle handling

A further quality aspect of this joint-venture equipment is can handling: as with PET bottles, the trend here has long been for the use of less and less material. While a common top load for cans used to be 800 newtons, today’s standard is down to 675 – or even 550 newtons for the newest lightweight cans. “Increasingly thinner wall thicknesses are a real challenge when it comes to gentle container handling,” Härtel states. “They’re more difficult to guide. And with the pre-lacquered cans that run through our machines, even the slightest amount of damage is immediately visible.” This isn’t a problem for the SmartCan Eco, however: a number of functions specially designed for processing lightweights give it the light touch it needs. For instance, the belt and screw drives have been separated to enable different forms of lubrication – just one example of the diverse drive technology added to permit extremely smooth container conveying.

Improved hygiene

What stands out especially on the modified block is the reduced hygiene area, now up to 93% smaller than classic housings. The tight-fitting cladding and relatively small surfaces are new. Moreover, between static and dynamic elements liquid locks are used in place of rubber seals. These prevent wear and soiling by particles. Air filter blowers introduce sterile air into the hygienic zone with a slight positive pressure of five pascals. In combination with extraction units positioned underneath the machine, a targeted flow of air is produced with a rate of about 100 exchanges per hour.

Increased efficiency

The most significant positive effect on the new filler/seamer block’s degree of efficiency is chiefly generated by the greatly reduced hygiene area. Together with reliable full sealing of all windows and joints, it permits simultaneous interior and exterior cleaning for the very first time. “To date, we only used caustic cleaning in product-conducting parts,” Härtel states. “Now we can sanitize the filler carousel, conveyors and transfer stars with the same medium. Instead of being poured down the drain and ultimately discharged to the sewage plant as was previously the case with exterior cleaning, all of the cleaning solution used is collected in the housing, pumped back to the CIP system and reused from there.” This notably saves time, water and chemicals over the interior CIP and exterior foam cleaning processes that used to run separately from one another. Caustic and/or acid are also used for intermediate cleaning – both of which are of course reusable. This renders a dedicated foam station superfluous.

A further advantage of the downsized hygiene area is that instead of the eight to ten air filter blowers formerly required, it now only needs one to two to ensure a permanent exchange of air. This means lower electricity consumption, less frequent filter replacement and reduced maintenance effort. Despite the miniaturization of the hygienic zone, care has still been taken to ensure excellent access for format changeovers and servicing. This applies in particular to all filling valves: as compact components – incidentally identical to those used on the KHS Innofill Can DVD filler – they can be accessed without restriction.

Flexibility is writ large: the SmartCan Eco is an all-rounder for the low-oxygen filling of beer and still and carbonated beverages. Temperatures range from four to 20°C for beer, alcohol-free beer and mixed beer beverages through a maximum of 24°C for soft drinks to 95°C for the hot filling of juice, tea or coffee beverages, for example.

On the currently blocked Ferrum FS14 seamer and on the next size up, the FS18, format changeovers are largely automated and recipe-controlled. Besides improving on hygiene, above all this takes up only about half of the time previously needed. The weight of the change parts has also been considerably reduced: today, none weighs more than twelve kilograms, literally making light work for operators.

All told, Härtel concludes, first and foremost it’s the even better level of hygiene that makes for greater efficiency. “The more hygienic filling is, the longer you can produce for. The machine used to operate eight hours at a time; now it runs for far longer. To put it simply, more production time and less cleaning time mean that however you look at it, at the end of the week you’ve more cans on the pallet.”

Manfred Härtel (source: Frank Reinhold)

“Depending on the seamer, our filler/seamer block can be used for outputs of between 60,000 and 135,000 cans per hour,” explains Manfred Härtel, filling product manager for KHS Group in Bad Kreuznach, Germany.

Download image (JPG, 81 KB)SmartCan Eco by KHS/Ferrum (source: Christian Sperling)

The KHS Group and Ferrum Packaging AG are setting new standards in can filling with the new SmartCan Eco.

Download image (JPG, 47 KB)Filling technology (source: Christian Sperling)

Compared to its market competitors, the SmartCan Eco is primarily noted for the high quality of its proven reliable and durable filling technology.

Download image (JPG, 68 KB)