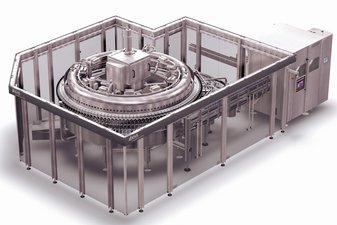

Innofill Can DVD can filler

Perfectly prepared for the future.

Good to know

Our Innofill Can DVD is characterized by its high degree of flexibility and viability for the future. This computer-controlled can filler is able to process many different types of product. With it you can fill beer and also carbonated soft drinks, juices, still beverages and even tea and coffee into cans quickly and efficiently. Our system is capable of filling up to 135,000 cans per hour.

Well thought out

The Innofill Can DVD sets new standards in relation to hygiene and product safety. The can transfer parts are fitted on stable pipe columns and the servodrive motors for the transfer components are integrated into the columns. This enables optimum accessibility and cleanability. The filler operates according to the volumetric filling principle. This gives you maximum filling accuracy and freedom in your choice of can to be processed. Highly dynamic filling also ensures consistently uniform filling results in all capacity ranges and operating phases. In addition, all processing sequences are automated. All processes are also documented and reproducible for you at all times. Perfectly tailored to your exact requirements 24/7.

Further reading

Flagship brewery

In erecting one of the biggest and most modern breweries in China, Carlsberg Asia and KHS are penning a further chapter in their long, shared story of success.

Learn moreConvincing

- Reduced CO2 consumption with low oxygen pickup thanks to a new CO2 purging process for the best possible technological values

- The universal centering bell enables various diameters of can to be processed

- The volumetric filling method for exact fill levels.

Sustainable

- Minimum changeover time saves your valuable time in the long run

- Energy-saving warm filling at up to 20°C versus conventional recooling

- Hygienic design for easy resource-saving sanitizing

Good to know: with our platform system you can add modules to your machinery to allow you to flexibly process further beverage types or container sizes in the future. This means that you are all set up to meet constantly changing future market challenges today. Invest in the long term and benefit from efficient maintenance and an optimum supply of spare parts – for increased line availability.

Options

-

Hygiene housing

Brief description: mit hochgezogenen Mantelblechen

Benefits: 40% smaller volume, good access

Convincing: Optimum alignment of the sterile air flow, high standard of hygiene

Sustainable: Fewer FFUs, less cleaning effort thanks to smaller volume and small surfaces

-

Automatic CIP plates

Brief description: Rinsing plates are automatically retracted and extended

Benefits: Fast retraction and extension of the CIP rinsing plates saves time

Convincing: No operator intervention in the hygiene area

Sustainable: Rinsing plates are activated at the press of a button, saving time and resulting in higher availability for production

-

CO2 exhaust

Brief description: CO2 extracted in the service module area and on the seamer

Benefits: Machine safety; low CO2 concentration in the machine environment

Convincing: Safe working conditions

-

Hot filling

Brief description: Hot filling of juice, tea and still beverages

Benefits: Greater flexibility

Convincing: Safe filling of sensitive beverages

Sustainable: Broad filling spectrum on one machine

-

Automatic foam cleaning

Brief description: Automatic SOP cleaning of the outer surfaces within the cladding

Benefits: Fast, automatic cleaning without an operator

Convincing: Reproducible cleaning results as functions monitored

Sustainable: Low media consumption, safe and reliable function

Images & videos

Blocked content

This YouTube video is blocked because you have not agreed to the YouTube service. By clicking the button you can change the cookie settings and play the video.

Blocked content

This YouTube video is blocked because you have not agreed to the YouTube service. By clicking the button you can change the cookie settings and play the video.

Consumables

KHS MULTI GREASE 01

KHS MULTI GREASE 01 is an high performance extreme pressure lubricant. It is suitable for centralised lubrication systems.

Material numbers: 301142150102, 301142150106, 301142150108

KHS SEAL & SILICONE GREASE 04

KHS Seal & Silicone Grease 04 is a high performance silicone lubricant specially developed for the grease lubrication and sealing of tapes, valves and fittings with EPDM seals (ethylene-propylene-diene rubber) in the food and beverage processing and packaging industry, with good resistance to hot water, steam and disinfectant solutions.

Material numbers: 301142150403

KHS GEAR FLUID 150

KHS Gear Fluid 150 is a fully synthetic high performance gear oil with EP properties.

Material numbers: 301142110912

KHS GEAR FLUID 220

KHS Gear Fluid 220 is a fully synthetic high performance gear oil with EP properties.

Material numbers: 301142110507

KHS GEAR FLUID 460

KHS Gear Fluid 460 is a fully synthetic high performance gear oil with EP properties which have been specially developed for use in machinery used in the food and beverage processing and packaging industry.

Material numbers: 301142110207, 301142110209