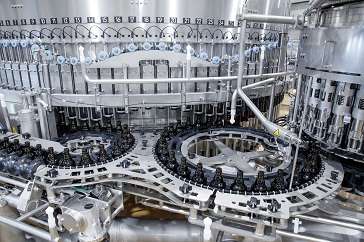

Innofill Glass DRS

Our efficient glass bottler which saves on energy and resources when filling beer beverages and soft drinks

Good to know

Our flexible high-performance filler processes beer, mixed beer beverages and soft drinks in glass quickly and efficiently thanks to the new method. It has a capacity of up to 80,000 bottles per hour.

Well thought out

The Innofill Glass DRS can be tailored to your specific requirements and is supplied as a single machine or in combination with a bottle rinser for various output capacities. Additional closure systems can also be retrofitted as an option as and when required. If you also want to save energy and media, you can operate the bottle filling machine with our vacuum pump. With our new filling system you enjoy optimum beverage quality while drastically cutting your CO2 consumption by up to 60%.

Further reading

Low-oxygen zone

Thanks to the new Innofill Glass DRS ECO from KHS even the seasoned brewers at OeTTINGER are discovering the taste of their beer anew.

Learn moreConvincing

- Future-proof machine which is extremely flexible thanks to its modular design

- Excellent technological results thanks to the filling method

- No condensation on the bottles through warm filling at 20°C

Sustainable

- Cut your CO2 consumption by up to 60%

- Reduce your energy consumption at the vacuum pump by up to 20%

- Reduce the amount of product loss

Good to know: with our platform system you can add modules to your machinery to allow you to flexibly process further beverage types or container sizes in the future. This means that you are all set up to meet constantly changing future market challenges today. Invest in the long term and benefit from efficient maintenance and an optimum supply of spare parts – for increased line availability.

Options

-

OPTICAM

Brief description: Monitors the foaming unit with an automatic, camera-assisted controller

Benefits: Consistent beer quality through the adaptation of parameters – without the need for any manual intervention

Convincing: Water consumption and product loss reduced while maintaining maximum quality

-

SOFTSTOP

Brief description: Gentle braking of the glass bottle flow at full capacity

Benefits: Higher system efficiency, regardless of the filler capacity and bottle diameter

Convincing: Consistent filling quality with high machine efficiency and gentle bottle handling

-

DIAS

Brief description: Constant monitoring of all filling stations

Benefits: Holistic quality control and automatic detection of broken bottles

Convincing: Preventive maintenance through early detection of process deviations