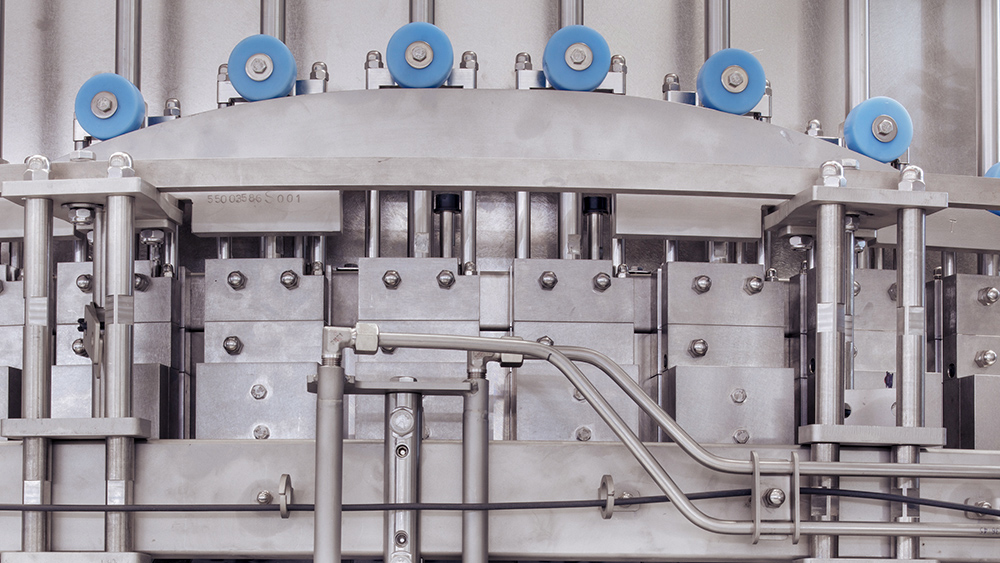

Innofill Glass NRF/DNRF – flexible filling systems for carbonated and non-carbonated beverages

Gentle hot and cold filling with precise fill heights and maximum product quality

Good to know

The Innofill Glass NRF filling system is ideal for the pressureless filling of non-carbonated beverages such as fruit juice, teas or still soft drinks. The long-tube filling principle means that the process is extremely gentle and perfectly suitable for hot filling. An electrical probe on the filling tube precisely regulates the fill height. With this bottom-up filling method, foaming and oxygen pickup are minimal.

The Innofill Glass DNRF combines the benefits of the NRF system with the option of also filling carbonated products such as soda pop under pressure – for maximum flexibility for practically all kinds of beverage.

Well thought out

Pneumatic control of all valve functions means minimum maintenance effort and low wear. Precise fill heights are ensured by filling tubes with integrated electrical fill level probes – a plus when it comes to product quality coupled with less product loss. All processes are fully automated, documented and reproducible at all times. This gives you a reliable and efficiently adaptable system tailored to all product requirements.

Convincing

- Gentle long-tube filling for minimum oxygen pickup

- Hot filling possible at temperatures of up to 95°C

- DNRF: optional warm filling of carbonated beverages at 20°C maximum prevents condensation

Sustainable

- No need for pre-evacuation lowers resource consumption

- A hygienic design means fast and efficient cleaning

- Low foaming and precise fill heights reduce product loss

Worth knowing: the platform system enables modules to be added to the system so that it can be flexibly adapted to new beverage types or container sizes for a long-term, secure investment. Efficient maintenance processes, an optimum supply of spare parts and high degree of line availability make for economical operation in the long run.