High performance meets energy-efficient robotics

KHS Innopal PLR ready for serial production

- System successfully established on the market

- Further developments in format changeovers and pallet conveying

- Innopal PLR combines palletizing and cutting-edge robot technology at the highest level

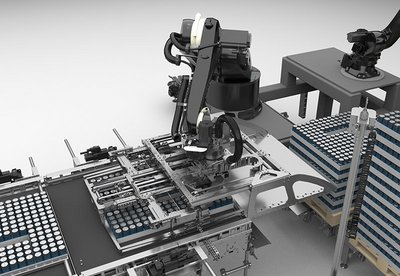

Dortmund, September 17, 2025 – The Innopal PLR has complemented the KHS GmbH product portfolio since 2022. The Dortmund systems provider has now readied the high-performance palletizer for serial production – with targeted further developments and positive customer feedback.

For KHS, the market launch of the Innopal PLR marked a significant milestone, as Ralf Kretschmann, product manager for palletizing technology at KHS GmbH, emphasizes. “The Innopal PLR is a new phenomenon and figurehead for KHS palletizing technology. It caters for the high-capacity range, combines this with a low-level infeed and with its robotics it’s also highly automated.” This smart system thus gives users a number of benefits, particularly regarding efficiency and automation, plus work safety and ease of operation.

KHS: many years of expertise in palletizing and robotics

The Innopal PLR specifically serves the high global demand for robot systems in palletizing. “These were and still are predominantly configured for the low-capacity range,” explains Kretschmann. With the Innopal PLR, KHS has consciously taken a different approach. With its latest robot generation that has a throughput of up to 650 layers per hour for PET bottles and cans, it’s perfectly designed for customers who want high performance in this field. Line capacities of up to 240,000 containers per hour can now be achieved by a single palletizer with high stacking accuracy.

The palletizer grouping system is equipped with the new InnoPET iflex option that enables fully automated format changeovers. This technology also permits the gentle processing of various sustainable packaging systems such as PaperPack, KHS NMP (Nature MultiPack) and trays without film. “To switch formats, all the operator has to do is choose the required configuration on the HMI. The robots then select the appropriate grippers unassisted and swap these over,” Kretschmann says. This high degree of automation has a positive impact on the efficiency, safety and speed of format changeovers. It also eases the operator’s workload.

Unique combination

The Innopal PLR combines the advantages of an automated high- performance palletizer with a low-level pack infeed. During development, KHS deliberately did away with the need for the platform that’s standard in the high-capacity range, with clear benefits for work safety and ease of operation.

The Dortmund engineering company also attached great importance to safety in the further development of the pallet conveyor to the Innoline PTR Series II. “Among other things, we subjected all crushing and cutting points on both the conveyor and in its immediate vicinity to a thorough assessment and subsequently reduced these. For us, it’s especially important that the Innopal PLR meets the highest standards of industrial safety. What’s more, in the new concept all conveyors are frequency-controlled and provide an extended diagnosis function for greater line availability,” states Kretschmann.

Extensive one-stop service

The line-compatible palletizer is also convincing when it comes to versatility. It processes the three classic container segments (can, PET and glass) and all standard pallet formats. The robot system is also designed for a long service life and future viability and is extremely low maintenance. Optional layer pad processing is also performed by a robot application.

This technical flexibility is supplemented by KHS’ extensive portfolio of services based on over 30 years of robotics experience in palletizing. The Dortmund turnkey supplier provides its customers with holistic support – from planning through installation and commissioning to maintenance and the supply of spare parts. KHS has come up with a dedicated tool specially for line design. “We’re familiar with the challenges our customers face. Space in the production shop is limited and often even more restricted by pillars and the like,” Kretschmann confirms. KHS has thus devised and tested a number of different layout variants for the Innopal PLR in advance that satisfy practically all imaginable customer requirements. The palletizing team also makes use of KHS’ proven 3D line design setup.

High demand

The Innopal PLR has now successfully established itself on the market, with the palletizer chiefly popular in the regions of Asia, Europe and North and South America. “With our customized systems, we cover a broad spectrum of layout variants, performance requirements and processing programs. This means that we’ve reached our goal: numerous optimizations have been made and fully integrated into the series version of the Innopal PLR – in time for drinktec,” says Dr. Mohamed Astitouh, head of the Packaging and Palletizing Product Center and managing director of the KHS production site in Worms. Appropriately, then, KHS will be presenting the further-developed model of its future-proof, high-performance palletizer for the very first time at drinktec, Munich, from September 15 to 19.

Ralf Kretschmann (source: Frank Reinhold)

“To switch formats, all the operator has to do is choose the required configuration on the HMI. The robots then select the appropriate grippers unassisted and swap these over,” says Ralf Kretschmann, product manager for palletizing technology at KHS GmbH, of the high degree of automation on the further-developed Innopal PLR.

Download image (JPG, 56 KB)Dr. Mohamed Astitouh (source: Frank Reinhold)

“With our customized systems, we cover a broad spectrum of layout variants, performance requirements and processing programs,” says Dr. Mohamed Astitouh, head of the Packaging and Palletizing Product Center and managing director of the KHS production site in Worms.

Download image (JPG, 79 KB)Innopal PLR (source: Frank Reinhold)

With the further-developed Innopal PLR, line capacities of up to 240,000 containers per hour can be processed by a single palletizer.

Download image (JPG, 152 KB)Robot head (source: Jan Schwerdtfeger)

With its latest robot generation that has a throughput of up to 650 layers per hour for PET bottles and cans, the Innopal PLR is perfectly designed for customers who want high performance in this field.

Download image (JPG, 106 KB)