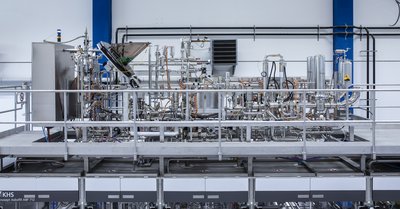

KHS Innofill PET ACF-L linear aseptic filler

Highly efficient aseptic filler for the gentle, recontamination-free bottling of high- and low-acid products

Good to know

A healthy lifestyle and increasing mobility in society are resulting in a steadily growing demand for sensitive and functional beverages in many different plastic bottles. Our Innofill PET ACF-L assures you a reliable filling process that satisfies your extremely high hygiene requirements. It fills milk, mixed milk, sports, yogurt and coffee beverages and fruit and vegetable juices into PET and HDPE bottles in outstanding quality. The filling machine yields excellent results for capacities of up to 28,000 bottles per hour holding between 100 and 2,000 milliliters.

Well thought out

The compact linear design of this filling and capping machine makes it ideal for frequent format changeovers and smaller product batches. At the same time, it provides maximum aseptic safety thanks to its very small aseptic zone. Depending on market requirements, the machine can be equipped with a closure system for plastic screw caps and/or foil seals.

Further reading

Much more

Numerous innovations make for efficient, flexible and safe filling of sensitive beverages – such as the Innofill PET ACF-L, for example.

Learn moreConvincing

- Precise sterilization of bottles and closures with H2O2 aerosol

- Independent of the bottle design, thus maximum process flexibility

- Compact design and extreme ease of operation

- Maximum aseptic safety within a minimum amount of space thanks to the compact linear design

Sustainable

- Profit in the long term from low operating costs while enjoying a high level of production reliability

- Do away with the need for extra water during the production cycle

Good to know: with our platform system you can add modules to your machinery to allow you to flexibly process further beverage types or container sizes in the future. This means that you are all set up to meet constantly changing future market challenges today. Invest in the long term and benefit from efficient maintenance and an optimum supply of spare parts – for increased line availability.

Options

-

Blocked variants

Brief description: The filling and capping machine can be blocked with a standard KHS stretch blow molder. Depending on requirements, an additional bottle infeed such as a bottle uprighter or KHS InnoPET Plasmax coating machine can be connected to the block.

Characteristics: In the transfer module rotary bottle conveying is converted into linear, cycled bottle conveying. An extra bottle infeed or coating machine is connected by an air conveyor.

-

Application of nitrogen to stabilize plastic bottles

Brief description: The unit doses liquid nitrogen after filling.

Characteristics: This process allows the bottle weight to be reduced compared to a bottle without internal pressure and the product shelf life is lengthened.

-

Servo capper

Brief description: On the servo capper each capping element is controlled by a vertical/rotary servomotor. This enables all relevant capping process parameters for each bottle to be processed to be electronically monitored and controlled in real time.

Characteristics: At the end of the capping process the process parameters are evaluated and documented and any incorrectly capped bottles marked for rejection.

-

Closure systems for plastic screw caps and/or aluminum foil seals

Brief description: The filler can be equipped with a closure system for either plastic screw caps or aluminum foil seals. Depending on market requirements, the machine can also be fitted with both closure systems.

Characteristics: The caps are sterilized with hydrogen peroxide (H2O2) and then dried with hot sterile air before they are applied to the bottles.

-

Production data acquisition

Brief description: Hardware and software are added to the production data acquisition (PDA) system to allow media values to be measured and recorded.

Characteristics: The following media values are acquired and logged by the PDA system:

- CIP media (pressure, conductivity, flow rate)

- Compressed air (consumption)

- Steam (consumption)

- Water (consumption)

- H2O2 (consumption)

- Electricity (consumption)