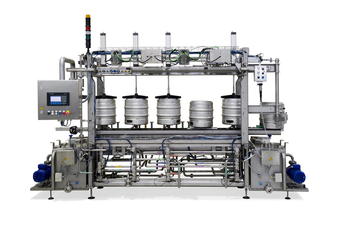

KHS Innokeg Transomat keg system

The perfect duo – our keg system for washing and racking

Further reading

Off to the country!

Canadian brewery Molson Coors processes a number of different keg shapes and sizes on its kegging line in Chilliwack outside Vancouver.

Learn moreGood to know

The KHS Innokeg Transomat keg system enables you to thoroughly clean and gently rack 7-liter – ½ bbl (approx. 58-liter) kegs with three, five or six active washing stations and one filling station. This efficient combination allows you to rack optimally prepared kegs with almost any product - from beer through soft drinks and wine to water. Our flexible, linear machine can be installed with one or two lanes (mono/duo series), either individually or in a group, giving you capacities of 55 to 800 kegs per hour to meet all requirements.

Well thought out

Our reliably monitored cleaning technology with pulsating sprays gives you optimum results and therefore microbiological safety and cleanliness for your products. The use of a local control system saves you having to install extra switch cabinets. Our KHS Direct Flow Control filling system ensures a precise and gentle filling process, perfectly complementing the performance of the KHS Innokeg Transomat.

Convincing

- Over 40 years experience and continuous development give you optimum process cycles for refillable and non-refillable containers

- Hygienic and maintenance-friendly design for microbiological safety

- Practically format-part-free keg handling to a large extent with an optional active intake

Sustainable

- Produce a higher-quality product with a longer shelf life and greater cost effectiveness thanks to the patented KHS Direct Flow Control system (DFC) and also save up to 40% CO2

- Save up to 80% water using optional water cascading systems

- Invest in solid and proven technology which has been shown to enable the machine to be used for very long periods and allows all common non-refillable containers to be processed