Premium packaging technology for a premium spirit

Beam, the largest liquor company in the USA, relies on KHS packaging technology

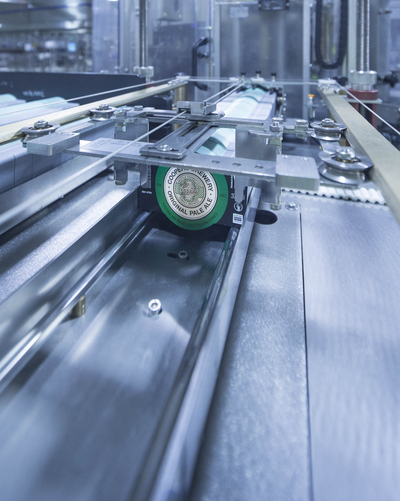

Georg Zuzok*Steve Humbert** In 1795 Johannes Jacob Böhm from Germany (or Jacob Beam, to give him his Americanized name) sold his first barrel of whiskey in Kentucky in the United States of America, writing the first chapter of what was to become the success story of Jim Beam brand whiskey, which shows no signs of ending; Jim Beam is currently the world's number one bourbon whiskey and is now produced by Beam Inc. in its seventh generation. The company's first brand, Jim Beam White Original, has now not only been joined by a number of other Jim Beam bourbons in the Beam range but also several other brands of spirit. Most of the brand products are still produced and bottled in Kentucky, with Beam's main production site being the Old Grand Dad plant founded in Frankfort, Kentucky, in 1901. Each year approximately 12 million cases of spirits are shipped from here to retailers, restaurants and bars and consumers (a case contains nine liters on average). This means that the Frankfort facility alone bottles and packages over half of all Beam spirits produced in Kentucky and about 30% of those produced worldwide. Byron DuBois, manager of the Frankfort plant, says, "So that we can manage our high output with any reliability, we need technical equipment we can fully depend on. This is why we opted for wrap-around packers from KHS – among others –when we recently invested in new packaging technology. Since 2010 we've ordered one KHS packaging system after another. We now have four KHS wrap-around packers at our plant which not only perfectly package our high-quality products but also operate with the utmost efficiency. We're extremely pleased with them." *Head of Market Zone Americas, KHS GmbH, Bad Kreuznach, Germany. Phone: +49 671 852 2202 **Head of Packaging Technology, KHS USA, Inc., USA. Phone: +1 513 288 8931 50% of all bourbon produced in Kentucky is Jim Beam In the USA bourbon whiskey is a national spirit with tradition, a fact confirmed in 1964 by the United States Congress. Ninety-eight percent of America's bourbon distilleries can still be found in Kentucky and one local saying has it that there are more barrels of bourbon here than there are inhabitants! Around half of the bourbon produced in Kentucky every year is a Jim Beam brand, with the range including the classic Jim Beam White Original and several other variants, such as Jim Beam Rye, Jim Beam Black, Jim Beam Devil’s Cut and Red Stag by Jim Beam in the flavors Black Cherry, Honey Tea and Spiced. Worldwide sales of Jim Beam spirits at more than seven million cases In 2012 Beam sold more than seven million cases full of Jim Beam spirits worldwide. Sales are expected to again rise in 2013 as the demand for bourbon is continuing to grow both in the USA and throughout the rest of the world, especially on traditional markets such as Germany and Australia. This high turnover of Jim Beam is backed by targeted marketing campaigns chiefly aimed at adults under the age of 30 that are run in all corners of the globe. Extremely wide range of spirits Although Jim Beam brands make up the lion's share of Beam's revenue at 20% of total sales, the selection of bourbons has now been joined by an extremely wide range of other spirits. These include a number of established power brands, such as Maker’s Mark bourbon, Pinnacle vodka, Sauza tequila, Courvoisier cognac, Canadian Club whisky and Teacher’s scotch. There are also several rising stars in the Beam portfolio, such as Skinnygirl cocktails, Knob Creek bourbon, Hilbeggan Irish whiskey, Hornitos tequila and Cruzan rum, for instance. National specialties are DeKuyper cordials (USA), Larios gin (Spain) and Sourz liqueur (Great Britain). Largest spirits company in the USA and number four worldwide With all of these brands and many others besides Beam is the largest spirits company in the USA and holds fourth place among sellers of premium spirits worldwide. Beam employs 3,400 people all over the globe. In 2012 the company sold 38 million cases, realizing sales of $2.5 billion. Beam's activities are split across three sales regions, the USA being the most significant – as it always has been – with a sales share of 58%. North America is followed by the region Europe/Middle East/Africa at 22%, with Asia Pacific/South America running a very close third at 20%. Biggest Beam plant in Frankfort, Kentucky, with no fewer than four new KHS wrap-around packers Of the 21 million cases of Beam products produced in the USA per annum the plant in Frankfort, Kentucky, makes 12 million. Around 100 different brands of liquor are bottled and packed here and leave the premises in approximately 1,600 different sales units. Frankfort employs about 350 people on a site measuring around 350,000 m2. The plant's warehouse can hold about 21 million liters or 175,000 barrels. The production site has grown especially fast over the last few years, with its output doubling in just five years. Frankfort now operates nine lines in two or sometimes three shifts, four of which are equipped with a wrap-around packer each from KHS. Of these four packers two are Innopack Kisters WP A-H in the Advanced series which cater for Beam's high-capacity lines (these have rates of up to 70 cycles per minute). The other two are Innopack Kisters WP 030s which can run at up to 30 cycles per minute on the lower capacity lines. The two Innopack Kisters WP A-H machines at Frankfort package various sizes of glass and PET bottle into packs of 6 and 12, with the two smaller machines processing one size of PET bottle only as packs of 12. The Old Grand Dad plant packs a more or less equal number of PET and glass bottles. Says DuBois, "The popularity of spirits in PET bottles is continuing to rise. This is thanks to the many advantages of PET, such as its light weight and unbreakability. Another reason is that on first sight our PET bottles look hardly any different from glass bottles and thus have an excellent visual impact on consumers." First impressions both positive and lasting Whether glass or PET bottles are processed, according to John Ballard, maintenance manager at Beam Inc., investing in the company's four new Innopack Kisters wrap-around packers was an excellent idea. "As soon as they'd been installed at our plant, they all began producing to our fullest satisfaction," he smiles. "Our first impressions were both positive and lasting. It was therefore obvious that whenever we had to invest in a replacement packaging machine in the recent past, we always opted for KHS technology." The decision to procure the first Innopack Kisters WP A-H was reached in 2010. DuBois tells us more. "We first studied the system at a number of breweries which had been using it for some time. They were very pleased with it. We heard lots of positive comments and were able to have a good look at the technical setup. We soon realized that this really is a turnkey concept that has been worked out right down to the last detail and which with its great flexibility will stand us in good stead for the future. We therefore didn't hesitate any longer and placed our order with KHS." Wrap-around packers in the new Advanced machine series prove convincing in the high-capacity range At present the two Innopack Kisters WP Advanced machines only process the given bottle variants in packs of 6 and 12 – but this needn't always be the case. The packaging machines are predestined for use with all shapes, heights and widths of glass, metal or plastic container, can or carton and suitable for utilization not only in the beverage sector but also in the food and non-food industries. Another benefit of the Advanced series as far as flexibility is concerned is that the machine can be expanded by adding extra modules. "Even if we don't intend to change our concept," explains Ballard, "it's good to know that we can if we want to. For who can predict what the next decades will bring?" High ease of operation Of particular importance to DuBois is the operator-controlled format changeover concept. On a change of product the machine's operator panel tells the operator which and also where parameter readjustments must be made, thereby eliminating the need for paper lists of parameter settings and a check of all areas where readjustments may be necessary. An electronic display informs the operator as to exactly where and how these readjustments are to be made. Any play in the gear wheels or chains is taken into account in these instructions. Another significant benefit of Beam's new wrap-around packers is their outstanding accessibility and hygienic design. Identical servomotors with integrated servocontrollers provide many benefits The wrap-around packs are fed to the packers according to the accumulation principle and split into lanes. The products are then grouped by a multiservo sectioning unit. Another plus of packers designed along the guidelines of the Advanced series is that identical servomotors with integrated servocontrollers are always used. Combining servomotors and servocontrollers in one unit aids troubleshooting in the event of a fault as well as part replacement during maintenance. The stock of spare parts is also reduced. In addition, as the servocontrollers are no longer housed in the switch cabinet – as was previously the case – the amount of wiring in the packaging machines is greatly reduced and the switch cabinet can be smaller. Smiles Ballard, "We thought the use of identical servomotors with integrated servocontrollers a very positive aspect before we even made the investment. We really are profiting from this feature and from the higher level of machine efficiency this gives us, among other things." Upstream blank conveyor reduces operator involvement On the Innopack Kisters WP Advanced series the wrap-around cardboard blanks are separated just below the grouping station. The individual blanks are removed automatically by a belt system. Special belts with a good-grip surface that are driven by servomotor ensure that the blanks are perfectly indexed into the conveying chain. Optoelectronic sensors ensure highly reliable production throughout the entire blank conveying procedure. Beam decided to install a blank conveyor upstream of each of its packers. Ballard explains why. "The operators load up the conveyor and can then carry on with other tasks until the blanks have been processed. In our view this lower level of operator involvement is a huge plus." Very gentle, extremely precise packaging process After being indexed the cardboard blanks coincide with the arrival of the product groups formed in the grouping station. These product groups are held firmly in place and safely conveyed at all times by folding chains located in the front and rear case packing areas and equipped with cam-controlled folding pickups. At the same time, special folding cams hold both sides in place while the blanks and product group are combined. The packaging process in detail is as follows: as soon as a product group enters the blank, one of the folding pickups makes sure that the front of the wrap-around blank is folded up. At the same time, the products at the back of the formation are held securely by a rod. A second folding pickup then closes up the rear section of the box. Glue is then applied by special hot melt application heads and the front and rear sections of the pack are finally closed. The next step in the procedure is to fold and glue the lid flap. The fully formed cardboard box finally runs through the application pressure segment. This gives optimum production reliability and high machine efficiency. High degree of flexibility Beam may only process corrugated cardboard boxes at the moment, yet the system is also prepared for kraft cardboard cases which again leaves plenty of room for flexibility in the future. KHS is also happy to provide advice on particularly suitable cardboard materials. Consultancy services range from providing information on the type and strength of the cardboard for specific purposes to the box format, integrated perforations and possible partitions. Even more flexibility is provided by each Innopack Kisters WP A-H being able to form tray packs if needed. The only restriction here is that the edge of the tray must be at least 60 mm high. Most recent investment in two Innopack WP 030s also extremely satisfactory Back to DuBois. "As we see it the Advanced packer series on our high-capacity lines is convincing on all counts," he says. "And this is precisely what we tell interested visitors also because we're deeply convinced by KHS." Ballard adds, "We're also extremely satisfied with the two Innopack WP 030s we ordered recently. Advanced technology is not an issue here quite simply because we couldn't utilize its many advantages, as on these lines we only pack one size of bottle into wrap-around boxes of 12." Says DuBois, "The two Innopack WP 030s are also working just as we'd like them to. We have outstanding product quality, ease of operation and low noise levels. We'd go for these machines again for lines with a low output and small processing range." The entire Beam Group will profit The positive experience the Old Grand Dad plant has had with its KHS wrap-around packers has also been clearly conveyed to other members of the Beam Group. "It's always well worth sharing our experiences with others," states DuBois, "as this benefits the product quality and line efficiency at Beam plants all over the world."