The Next Generation

Innovative system for maximum hygiene requirements

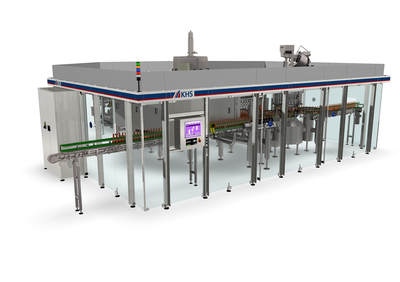

New KHS filler series for glass bottles Ludwig Clüsserath* Michael Beisel** In introducing a new, innovative, platform-based machine concept KHS is launching the next generation of filling machines for glass bottles – one that contains a whole range of extra benefits for its procurers. For instance, the Hygienic Design concept has been optimized in every conceivable way to enhance the filling quality and line availability through short cleaning times while reducing the cost of maintenance, power, water, and cleaning agents. These achievements are made possible by the use of modern, extremely low wear, and lubrication-free components which have been developed in close cooperation with highly specialized partners. One of the pioneers of the platform system is the automotive industry. Here, a platform is a shared, basic technical concept, the use of which permits the functions of various models to be enhanced and expanded. This definition can be similarly applied to the KHS platform. KHS has created a technical base upon which various computer-controlled KHS filling systems can be founded – while taking into account the individual criteria of specific filling methods. The first KHS filling system to profit from the innovative KHS Innofill Glass platform system is the computer-controlled Innofill DRS-ZMS pressure filling system which is predestined for the bottling of beer. The next step is to adapt the setup for further filling systems from KHS for soft drinks, water, wine, sparkling wine, and spirits. Here, the modular machine program also shortens production and processing times, thus resulting in shorter delivery periods. * Manager, Filling Technology Competence Center, KHS GmbH, BadKreuznach, Germany, Phone: +49 (671) 852-2501 **Filling Technology Competence Center, KHS GmbH, Bad Kreuznach,

Germany, Phone: +49 (671) 852-2205 Simplicity of the essence In the application of Hygienic Design simplicity is always of the essence. The following simple principles of construction are imperative: · Free access to all machine surfaces for cleaning, disinfection, and inspection · Elimination of construction areas that are hard to access where deposits and biofilms can accumulate · Easy runoff of liquids.

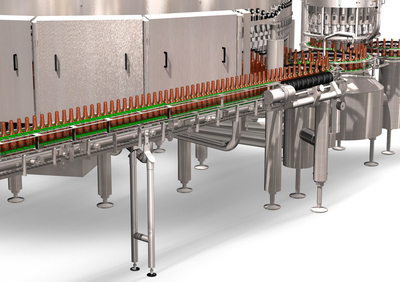

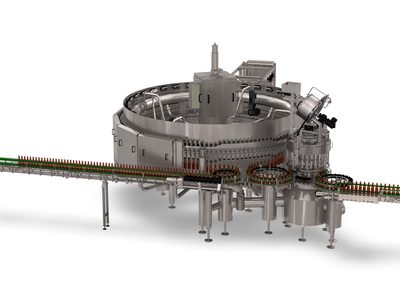

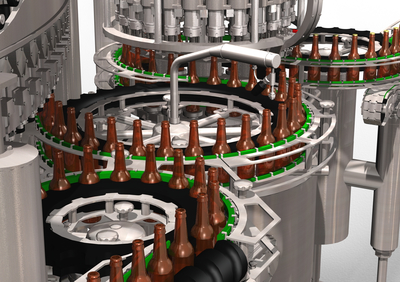

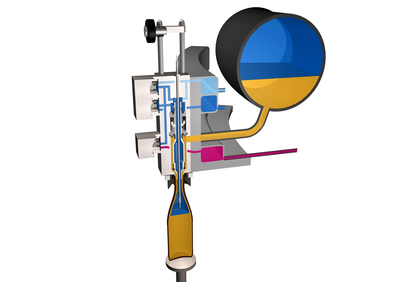

Protection for consumers and employees Hygienic Design is a major criterion for a company’s competitiveness where production costs are to be cut. The main concern, however, is ensuring product quality and protecting the consumer – and also the health and safety of the company’s own employees. New construction from top to toe In the construction of beverage machines to date attentions were usually directed towards optimizing the many individual component groups with regard to Hygienic Design, without taking adjacent machine parts into account. The problem here is that optimizing, modernizing, and converting existing machinery is always restricted if basic constructions are to be kept to. Hygienic Design is thus an incomplete concept. The answer was to completely rebuild one filler series, carrying out all stages of construction with Hygienic Design in mind right from the start, and totally disregarding any existing machinery component groups. Absolutely everything was subject to scrutiny, thoroughly reassessed, and finally implemented in innovative systems. Hygienic bottle conveying To put it simply, the task of the basic construction is to feed glass bottles into the machine, guide these to the filling and capping process, and then transport them out of the machine once filled and capped. This thus meant that one of the challenges of the overall design process was to engineer all parts related to bottle conveying according to the stipulations of Hygienic Design. Consistent implementation of the above resulted in a pipe construction that is open on all sides and therefore readily accessible for cleaning and disinfection. Any broken glass can fall straight to the floor and be easily cleared away. The stars and capper are connected by cross pipes with no flanges and secured with hygienic sealing systems on the exterior. All bottle format parts have been designed for optimum cleaning. Its weight now reduced, the construction is fixed into shape and position by easy-to-use locking pins. Container format parts can be quickly and simply changed without tools. Integrated automatic cleaning function A new, open-design, stainless steel conveyer takes the glass bottles directly to the feed screw. An automatic cleaning system can be integrated here, with the spray nozzles directed at all critical points on the bottle. The feed screw area, which separates the bottles into single file, demonstrates the maxim applied to the entire Innofill Glass construction: here there are no large surface areas but curves and slopes, allowing liquid to run off easily. In place of classic drive motors with rectangular gear housings the feed screw is powered by a servo motor mounted in a round, stainless steel casing. Bottle guide parts and glide strips have been engineered so that they can be perfectly accessed by automatic cleaning systems. Bottle glide and guide strip mounting systems avoid gaps and crevices where beer dregs can collect and microorganisms develop. Lightweight, open-structure machine carousel The lightweight construction of the lift cylinder table and tubular ring bowl also reduces the driving forces needed. The tubular ring bowl is also the perfect shape for efficient cleaning. The greatly reduced amount of material used ensures short heating and cooling phases during cleaning and sterilization, thus saving energy. The stability of the components that have been reduced in weight was verified using finite element analysis. Signals and capacities are electrically transmitted to the carousel by a maintenance-free rotary distributor. The heights of all exterior control cams and stop segments are adjusted by linear drive technology. A control ring running around the entire carousel, complete with an additional height adjustment motor, reversing gears, joint shafts, and lifting columns, is no longer necessary. The bottle lifting elements provide more space for the rejection of any glass fragments. The beverage and process media are fed in by height-adjustable scissor joints with aseptic sealing systems. Consistent implementation of the Hygienic Design concept results in a considerable reduction in the number and range of parts in the filler carousel – another step towards even more efficient sanitization and maintenance. Torque motors with plenty of advantages It was decided to use low maintenance, energy-efficient torque motors for all transfer stars and the capper, as torque motors have a number of advantages. Torque motors are direct drives with very high torques – as the name suggests – and relatively low speeds. In torque motors the rotor opposite the stator is driven by a magnetic field. As a result, there is no mechanical friction, thus reducing wear, making maintenance easier, and lengthening the service life of the device. Gears and couplings are no longer required. If we were to compare the energy efficiency of torque motors with that of conventional electrical motors, torque motors achieve much better results. The efficiency of the former is 96%, with that of conventional motors just 85%. This means that where torque motors are used, customers can reckon on making savings in energy of up to 20%. Another major advantage of torque motors is their hollow shaft design. Each motor has an opening through its center which in the new Innofill Glass is used to supply media. All beer filling systems have a high pressure injection unit which injects a jet of water into the filled bottles before they are sealed. This causes foam to form which specifically displaces air and thus oxygen from the bottle neck. To date the nozzle of the high pressure injection unit was affixed to the filler carousel or crown cork capper which meant that there were fittings, feed systems, hoses, and fastening elements in the critical open bottle area. This wasn’t exactly conducive to thorough cleaning. By using torque motors the aforementioned components are now situated outside the hygienically critical areas. All that can now be found in the open bottle area of the transfer star are a tubular, easy-to-clean support arm and the high-pressure nozzle. The engineers behind the Innofill Glass platform also envisage introducing media for foam cleaning through the center of the torque motor to other stars within the system. Further optimization of the Innofill DRS-ZMS filling principle In the filling system product, gas, and CIP media are fed in using hygienic, gapless sealing systems which do not allow any deposits to accumulate. When adapting the computer-controlled, pneumatic Innofill DRS-ZMS pressure filling system to the newly developed Innofill Glass series, the main features of the filling principle were maintained. The Innofill Glass DRS-ZMS operates with fill level probes. The pressurizing process with inert gas is preceded by triple pre-evacuation and double CO2 purging. After pressurization, the liquid valve opens and conducts the product over a swirler to the inner walls of the bottle. High valve filling outputs are achieved during the fast filling phase in the uncritical, cylindrical part of the bottle. A slow filling phase takes place in the narrow bottle neck for exact fill level measurement, which is initiated by a probe signal. A pulse from the probe closes the liquid valve at the precise fill level. This is followed by pre-snifting and final snifting. Pressure-controlled snifting takes place with little foam. The filling process is carried out independently of speed. The filling phase setpoints and thus the fill levels for all valves can be changed centrally even during the filling process. Integration of great new features The swirler that forms a film on the bottle wall has been aerodynamically optimized through modification of the number and shape of its blades. This enables improved, calmer, low turbulence filling and also ensures minimum oxygen pickup in the product. At the same time the filling speed in the fast filling phase is more precisely adapted to the specifications of the product to be filled and the fill level quality has been perfected. These benefits are further complemented by larger expansion spaces within the filling valve. Targeted Hygienic Design also again ensures simplified cleaning of the filling valves from the outside thanks to sloping surfaces and bell rods which are open on the exterior, among other things. All functions within one filling station are contained in one unit which can be completely removed or attached by simply loosening or tightening two cap nuts. In doing so, all media and pneumatic connections are automatically severed or restored, making any separate connecting of hoses unnecessary. Another feature of KHS filling systems is their low number of functional elements (pneumatic cylinders) within each filling station. This saves time and money during maintenance. Electrical elements perfectly separated from the filling area There are no electrical elements, cables, or pneumatic supply hoses whatsoever in the filling valve and bottle area. The pilot valves that control the filling process are arranged in a protected area which is completely encapsulated in its own housing and thus deliberately separate from the actual filling area. There is thus no machine downtime due to unfavorable climatic conditions. Instead, machines have a long service life and provide constant availability. The central control unit is protected by a stainless steel housing positioned in the center of the filler. Compact valve manifold saves 50% of floor space Furthermore, in conjunction with the new Innofill Glass a compact valve manifold is used that takes up 50% less floor space than the valve manifold included to date. This is because the fittings here have been constructed vertically instead of horizontally. This not only reduces the footprint but also has the additional advantage that all fittings for maintenance and inspection can be accessed more easily than they have been. The new compact valve manifold is fitted directly adjacent to the filler cladding. This keeps distances for media traveling from the valve manifold to the filler carousel deliberately short, in turn making cleaning fast and efficient.

Modular vacuum pump for pre-evacuation In the past fillers were equipped with a vacuum pump selected to suit the specific filling capacity. The result was that a number of different types and sizes of pumps were in use, for which spare parts had to be stocked. In the new filler series only one single type of pump is now being employed, which depending on the output can be installed up to three times in parallel. This saves costs, space, and enables a speedy supply of spare parts. By shutting down pumps that are not required in certain operating states and during a partial load the amount of electricity and water consumed is also reduced. Another advantage is that should one pump in the vacuum system fail, the filler can still carry on producing at a lower filling capacity. The new generation of pumps is also available with the proven ECO process, permitting up to 98% less water to be used compared to the conventional water ring principle. Hygienic Design also applied to the crown cork capper The tried-and-tested basic functions of the KHS crown cork capper have been largely adopted. With a view to providing better access for cleaning, however, many individual elements have been designed so that they are more open. Belt drives for the agitator and other drive systems previously driven by belts or gear wheels have been replaced by closed servo motors. Modular expansion easy thanks to new capper systems A chief new feature of the new Innofill Glass series is that if a customer has invested in a filler with an Innofill KK crown cork capper and later decides to process other closures besides crown corks, this is no great feat! Capper systems can be extended with modules which are simply docked onto the platform. This feature has been designed so that open bottles do not have to pass through existing capper systems, as was previously often the case. They are conveyed straight past the cappers that are not required to the capping system of choice. All that has to be done is to adapt the free-standing exterior cladding, also designed on a module basis, to suit the new extension. Unobstructed view of all machine components The general advantage of the free-standing Makrolon or glass exterior cladding is that operators have an unobstructed view of all machine components. This view is so perfectly transparent as an open design has been selected for the bottle conveying, filling, and capping areas. Dirt and deposits can be immediately spotted from outside. Besides being easy to see through, in positioning the exterior cladding great care is taken to ensure that there is enough access space to the individual component groups for cleaning and maintenance. An intrinsic part of the cladding concept is that with suitable preparation the simple exterior cladding can be upgraded to create an enclosed sanitary room. Short startup and shutdown phases and fast product changeovers The consistent implementation of Hygienic Design in the new filler series for all systems that contain product and process gas, plus the use of hygienic sealing systems and fittings, is prerequisite for fast intermediate rinsing and cleaning processes when changing product over. Lines laid at an angle ensure that product passages are quickly emptied. With frequent changeovers of product to be filled, this saves a considerable amount of time. Fast installation and commissioning All told, the modular, open machine construction and the few complex functional units engineered with Hygienic Design in mind result in a much shorter amount of time needed to install the machine and commission it. Diagnostic system for the filling process As an option, the reference filling valves can be equipped with pressure sensors which continuously record the pressure characteristics during a filling process and transmit this to the monitor. This allows the course of processing during a filling to be permanently monitored right into the bottle. The actual vacuum achieved in the bottles and the correct course of the CO2 purging processes can be read out, for instance. This is an important aspect where low oxygen filling is called for. Other information visible on screen is the switching cycles of the pneumatic cylinders in the filling valves, the real process times of the individual filling stations, and the signal patterns on the filling level probes. Award-winning KHS operator panel in use The Innofill Glass platform system is controlled by the new, award-winning KHS operator panel (red dot award and iF award) with an integrated RFID system. The KHS panel excellently combines ergonomics, navigation, and design. The result is user-friendly machine operator prompting that makes use of buttons, colored graphics, easy-to-remember icons, and interactive handling instructions – all of which have been kept deliberately simple and are self-explanatory. The system is subdivided into several levels, thus providing access to varying degrees of viewing detail and different operating levels as the specific application requires. A new dawn for filling technology The development of the innovative KHS platform system Innofill Glass is heralding a new dawn for filling technology. Extreme importance has been attached to transparency and cleanliness for even greater product safety. This in turn complies with the efforts of the brewing industry to fill beer pasteurized in a flash pasteurizer and do away with pasteurization downstream of the filling and capping process. Optimum hygienic conditions give the required level of hygienic safety. As in the brewing industry the soft drinks, wine, sparkling wine, and spirits sectors will also profit from using the innovative KHS series to bottle beverages which are just as microbiologically sensitive . All companies will also benefit from the reduction in costs for filling generated by the new generation of filling systems. Cuts in energy, cleaning agents, and water, and minimized maintenance speak for themselves – and increase the availability of the line for actual production. The new series of fillers offers one advantage after another, not just allocating a pioneering position to KHS but also giving all KHS customers a clear competitive advantage on the market.