Wide-neck containers: KHS presents individual PET systems for the food sector

There is a definite trend towards PET and ever larger bottle neck openings: in the food sector, where to date glass filling was standard, manufacturers are increasingly favoring lightweight plastic.

- Further development of the InnoPET Blomax stretch blow molder

- Holistic expert consultancy with Bottles & ShapesTM

- Increasing demand for PET containers in the food sector

Can be blocked with other systems

Depending on user requirements the stretch blow molder can be blocked with other KHS systems – not just with the InnoPET Plasmax for container coating but also with the Innosept Asbofill for the hygienic filling of sensitive products, for instance. The new KHS chunk dosing unit for flexible product design, which adds fruit, vegetables or cereals, can also be integrated into the system. “We’re vastly expanding the application options and providing system solutions for new markets,” claims Haesendonckx. In combination with KHS’ Bottles and Shapes™ bottle design program the systems supplier provides all-round service. Together with the customer KHS develops individual PET containers specifically tailored for functionality. “We offer all producers of food and beverages in PET containers holistic consultancy from the design through technical engineering to production of their PET bottles,” says Haesendonckx. The aim is to produce bottles with a high level of brand recognition which clearly stand out from those of the competition, bottles which can be produced cost effectively through lightweighting and which have a high degree of consumer affinity. The preferential heating system developed by the KHS Group also ensures optimum material distribution and bottle quality while using less energy in the stretch blow molding process. Very precise neck orientation is possible specific to the application, even in the manufacture of very oval containers, assures Haesendonckx. This creates the best possible synchronization between packaging and line production.About the KHS Group

KHS is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. The KHS Group includes the following companies: KHS GmbH, KHS Corpoplast GmbH, NMP Systems GmbH and numerous subsidiaries outside Germany. KHS GmbH manufactures modern filling and packaging systems for the high-capacity range at its headquarters in Dortmund, Germany, and at its factories in Bad Kreuznach, Kleve and Worms. The KHS Group's PET expertise is pooled at KHS Corpoplast GmbH in Hamburg, Germany, where innovative PET packaging and coating systems are developed and produced. NMP Systems GmbH, a wholly-owned subsidiary of KHS GmbH based in Kleve in Germany, designs and markets new, resource-saving packaging systems for PET bottles. In 2016 KHS and its 4,995 employees achieved a turnover of around €1.18 billion within the Salzgitter consolidation. The companies in the KHS Group are 100% subsidiaries of the MDAX-listed Salzgitter AG corporation.Neck handling

Very precise neck orientation is possible specific to the application, even in the manufacture of very oval containers.

Download image (JPG, 225 KB)Wide-neck bottle

There is a noticeable trend towards ever larger bottle neck openings on PET containers for a whole range of products.

Download image (JPG, 142 KB)White wine in a FreshSafe PET® bottle

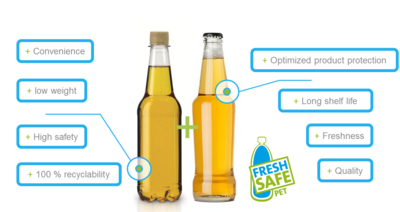

Sensitive products can also be filled into transparent plastic packaging thanks to KHS’ FreshSafe PET® coating method.

Download image (JPG, 1 MB)FreshSafe PET®

The FreshSafe PET® coating method combines the benefits of PET and glass bottles in a single product.

Download image (PNG, 474 KB)