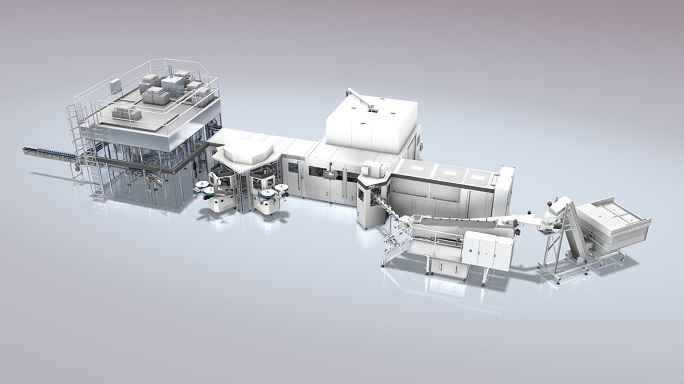

InnoPET TriBlock stretch blow molder/labeler/filler

Three in one: highly efficient technology for your PET bottles

Good to know

The InnoPET TriBlock performs three important functions for your PET bottles on just one machine. With it you can manufacture, label and fill PET bottles with carbonated and non-carbonated products – also lightweight containers of optimum quality. Format and product changeovers can be performed quickly and effectively. The InnoPET TriBlock stretch blow molder/labeler/filler is available for small and large product lines.

Well thought out

Thanks to the intelligent, direct blocking of the stretch blow molder, labeler and filler on the InnoPET TriBlock you boost your efficiency. You also make savings as the air conveyor common to classic machines is no longer required. An integrated air lock separates the filling and packing areas of the system.

Boost the efficiency of your PET filling and packaging line with our KHS InnoPET iflex modular automation concept with fast and reliable changeovers.

Further reading

Flexible AND efficient

With the help of automated format changeovers our stretch blow molder/labeler/filler block couples maximum flexibility with high efficiency.

Learn moreConvincing

- Modular, space-saving design for maximum flexibility

- Gaps in the bottle flow processed by the no bottle, no label function

- Easily adjustable cutting unit with self-sharpening cutters

- Segmented vacuum drum for fast format changeovers

Sustainable

- Efficient production of lightweight bottles with lower material costs and less effort

- No lost labels thanks to the no bottle, no label function

Good to know: with our platform system you can add modules to your machinery to allow you to flexibly process further beverage types or container sizes in the future. This means that you are all set up to meet constantly changing future market challenges today. Invest in the long term and benefit from efficient maintenance and an optimum supply of spare parts – for increased line availability.

Images & videos

Blocked content

This YouTube video is blocked because you have not agreed to the YouTube service. By clicking the button you can change the cookie settings and play the video.

Blocked content

This YouTube video is blocked because you have not agreed to the YouTube service. By clicking the button you can change the cookie settings and play the video.